DIY Round Table Base: A Comprehensive Guide to Building Your Own

Creating a custom round table can be a rewarding project, allowing for personalization of furniture to perfectly match a specific style and space. A crucial aspect of any table is its base, providing both structural support and aesthetic appeal. Constructing a DIY round table base offers numerous advantages, including cost savings, design flexibility, and the satisfaction of handcrafting a unique piece of furniture.

This article provides a comprehensive guide to building a DIY round table base. It will cover key considerations in design and material selection, offer detailed instructions for various construction methods, and address common challenges encountered during the building process. The information presented aims to empower individuals with the knowledge and skills necessary to create a stable, visually appealing, and durable base for their round table.

Key Considerations Before Beginning Construction

Prior to embarking on the construction of a DIY round table base, careful consideration must be given to several key factors. These factors will influence the design, materials, and construction techniques employed, ultimately determining the success and longevity of the finished product.

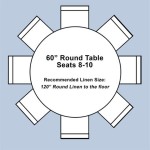

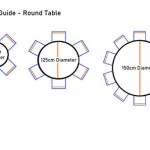

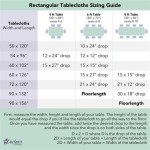

Tabletop Size and Weight: The dimensions and material of the tabletop are primary determinants of the base design. A larger tabletop necessitates a stronger, more robust base to provide adequate support and prevent instability. The weight of the tabletop material, whether it be solid wood, plywood, glass, or stone, must be factored into the load-bearing capacity of the base. Overlooking this aspect can lead to a base that is structurally inadequate, resulting in wobbling, sagging, or even collapse.

Desired Aesthetic and Style: The aesthetic of the table base should complement the tabletop and the overall décor of the room. Consider the desired style – modern, rustic, minimalist, or traditional – as this will influence the shape, materials, and finish of the base. Resources like design magazines, online furniture retailers, and home improvement websites can provide inspiration and aid in visualizing the desired outcome. Sketches and preliminary drawings are also helpful in solidifying the design concept.

Available Tools and Skill Level: Accurately assess the available tools and personal woodworking skills. Complex designs often require specialized tools and advanced techniques. Choosing a design that aligns with the available resources and skill level is crucial to avoid frustration and ensure a successful project. If the available tools or skill level are limited, consider opting for a simpler design or seeking assistance from a more experienced woodworker or professional carpenter.

Material Selection: The choice of materials significantly impacts the strength, durability, and appearance of the table base. Wood is a popular choice due to its versatility, availability, and aesthetic appeal. Different wood species offer varying levels of strength, hardness, and grain patterns. Softwoods like pine are generally less expensive but may be more prone to dents and scratches. Hardwoods like oak, maple, and walnut offer greater durability and a more refined appearance. Metal is another option, offering strength and a contemporary aesthetic. Steel and wrought iron are common choices for metal bases. The selection should also consider the desired finish. Wood bases can be stained, painted, or left natural, while metal bases can be powder-coated or painted.

Construction Methods for DIY Round Table Bases

Several construction methods can be employed to build a round table base, each with its own advantages and disadvantages. The choice of method will depend on the desired design, available materials, and the builder's skill level.

Tripod Base: A tripod base is a simple yet effective design, consisting of three legs radiating outwards from a central point. This design provides excellent stability and is relatively easy to construct. The legs can be made from wood or metal and can be tapered or straight. The central point where the legs converge can be reinforced with a metal plate or a wooden block for added strength. The angle of the legs determines the overall height and footprint of the base, and careful calculation is necessary to ensure stability. Tripod bases are well-suited to smaller to medium-sized round tables.

Pedestal Base: A pedestal base typically consists of a single central support column resting on a broad base. This design provides a clean, minimalist look and allows for ample legroom around the table. The pedestal can be made from a solid piece of wood, a hollow column constructed from plywood, or a metal tube. A wide, stable base is crucial to prevent tipping, especially with larger tabletops. The base can be circular, square, or multi-faceted. The connection between the pedestal and the tabletop should be robust, utilizing lag screws, metal brackets, or a combination of both. Pedestal bases are versatile and can be adapted to various styles, from modern to traditional.

Spider Base: A spider base is characterized by multiple legs radiating outwards from a central hub, resembling the legs of a spider. This design provides excellent stability and is well-suited to larger, heavier tabletops. The legs can be made from wood or metal and can be joined to the central hub using welding, bolting, or mortise and tenon joints. The number of legs can vary depending on the size and weight of the tabletop. A spider base can be more complex to construct than a tripod base or a pedestal base, requiring precise measurements and careful joinery. However, the added stability and visual appeal make it a worthwhile option for larger round tables.

Geometric Base: A geometric base utilizes intersecting shapes and lines to create a visually striking and structurally sound support system. This design can incorporate triangles, squares, polygons, or more complex geometric forms. The materials used can vary, including wood, metal, or a combination of both. Geometric bases often require advanced woodworking or metalworking skills and precise cutting and joining techniques. However, the resulting table base is a unique and eye-catching piece of furniture that can serve as a focal point in a room.

Addressing Common Challenges and Ensuring Stability

Building a DIY round table base is not without its challenges. Careful planning, precise execution, and attention to detail are essential to overcome these challenges and ensure a stable and durable finished product.

Wobbling and Instability: Wobbling is a common issue that can arise from uneven legs, a poorly constructed base, or an inadequate connection between the base and the tabletop. To address wobbling, ensure that all legs are of equal length and that the base is perfectly level. Use a level to check for any discrepancies and make adjustments as needed. Reinforce the connections between the legs and the central support structure using glue, screws, or metal brackets. If the tabletop is wobbling independently of the base, consider adding shims between the tabletop and the base to level it out.

Selecting the Right Joinery Techniques: Robust joinery is critical to the long-term stability and structural integrity of the table base. The appropriate joinery technique depends on the materials used and the skill level of the builder. Common joinery techniques for wood bases include mortise and tenon joints, dovetail joints, and lap joints. These joints provide a strong, interlocking connection between the wood pieces. For metal bases, welding is the preferred method for joining the metal components. Ensure that the welds are strong and free of defects. For simpler projects, screws and glue can be used, but they may not provide the same level of strength and durability as more advanced joinery techniques.

Calculating Weight Distribution: Accurate calculation of weight distribution is essential to prevent overloading and potential failure of the table base. The weight of the tabletop should be evenly distributed across the base. If the tabletop is particularly heavy, consider reinforcing the base with additional supports or using thicker materials. Online calculators and engineering formulas can be used to determine the load-bearing capacity of different materials and designs. Consulting with a structural engineer or experienced woodworker is also advisable for complex projects or when dealing with heavy tabletops.

Finishing and Protecting the Base: The finish of the table base not only enhances its aesthetic appeal but also protects it from moisture, scratches, and other forms of damage. For wood bases, consider applying a stain, paint, or clear coat to seal the wood and protect it from the elements. For metal bases, powder coating or painting is recommended to prevent rust and corrosion. Ensure that the finish is applied evenly and according to the manufacturer's instructions. Regular maintenance, such as cleaning and polishing, will help to preserve the appearance and longevity of the table base.

By carefully considering these aspects and following the detailed instructions provided, individuals can successfully create a DIY round table base that provides both structural support and aesthetic appeal. The satisfaction of crafting a custom piece of furniture that perfectly complements a specific style and space is a rewarding experience. The versatility of the designs and methods discussed allows for personalization and adaptation to individual needs and preferences.

Round Scalloped Fluted Pedestal Dining Table Diy Seats 10 12 People Black Ink Oak Finish

Diy Round Table Wood Designs

Diy Round Table For 75

How To Make A Diy Round Table Base With Fluted Design Hometalk

Salvaged Wood Beam Round Dining Table The Created Home

Diy X Base Circular Dining Table Jaime Costiglio

Diy Simplistic Circular Dining Table Kreg Tool

Diy X Base Circular Dining Table Jaime Costiglio

Diy Wood Slat Table Base And How I Treat All My Pine Banyan Bridges

Diy Wood Pedestal Table Base The Inspired Work

Related Posts