Here's an article focused on building a dining table base, written in an expository style with the requested formatting:

How To Build A Dining Table Base

Constructing a dining table base is a woodworking project that offers both utility and the opportunity to showcase craftsmanship. A well-built base not only supports the table top but also contributes significantly to the overall aesthetic of the dining area. This article outlines a comprehensive approach to building a sturdy and visually appealing dining table base, covering design considerations, material selection, construction techniques, and finishing options.

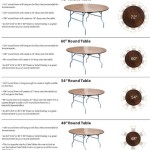

Before embarking on the construction phase, it is crucial to define the desired style and dimensions of the table base. These factors will dictate material requirements, joinery methods, and potentially the complexity of the project. Considerations should include the size and shape of the tabletop the base will support, the number of diners the table should accommodate, and the preferred aesthetic – whether it be modern, rustic, traditional, or something else entirely. Proper planning will save time and resources, ensuring the final product meets the intended specifications.

The primary function of the base is to provide stable and level support for the tabletop. Therefore, the design must take into account the weight distribution and potential for movement. A poorly designed base may lead to wobbling, sagging, or even structural failure. Furthermore, the base should allow comfortable legroom for diners; avoiding obstructions is paramount. These practical considerations are integral to a successful design.

Choosing the Right Materials

The selection of appropriate materials is paramount to the durability and visual appeal of the table base. Hardwoods are typically preferred for their strength, stability, and aesthetic qualities. Common choices include oak, maple, walnut, cherry, and ash. Each wood species possesses unique grain patterns, colors, and working properties. It is essential to consider these factors when making a material selection.

Oak, renowned for its strength and distinctive grain, is a popular choice for traditional and rustic designs. Maple, with its light color and fine grain, offers a modern and clean aesthetic. Walnut, prized for its rich, dark color and luxurious appearance, is often used in high-end furniture. Cherry, with its warm reddish-brown hue and smooth texture, is a classic choice that complements various styles. Ash, known for its flexibility and shock resistance, is a versatile option that can be stained to match various color schemes.

In addition to hardwood, other materials can be incorporated into the table base design. Metal accents, such as steel or wrought iron, can add a modern or industrial touch. Concrete can be used for a minimalist and contemporary look. Reclaimed wood can provide a rustic and eco-friendly option. The choice of materials should align with the overall design concept and desired aesthetic.

The dimensions of the lumber used in the base construction are also critical. The thickness of the legs, aprons, and stretchers should be sufficient to support the weight of the tabletop and withstand daily use. A general guideline is to use lumber that is at least 1.5 inches thick for the legs and aprons of a standard-sized dining table. However, this may vary depending on the design and the type of wood used. Consult woodworking resources and consider the load-bearing capacity of the chosen materials to make informed decisions.

Construction Techniques and Joinery

The method of joining the various components of the table base is crucial for its structural integrity and longevity. Several joinery techniques are commonly employed in table base construction, each offering varying degrees of strength and complexity. These include mortise-and-tenon joints, dovetail joints, dowel joints, pocket-hole joints, and screw joints. The selection of the appropriate joinery method depends on the design, the skills of the builder, and the desired level of durability.

Mortise-and-tenon joints are among the strongest and most traditional joinery methods. They involve creating a rectangular "tenon" on one piece of wood that fits snugly into a corresponding "mortise" on the other piece. These joints can be further strengthened with glue and wedges. Mortise-and-tenon joints are ideal for connecting the legs to the aprons and stretchers, providing exceptional stability and resistance to racking.

Dovetail joints are known for their aesthetic appeal and exceptional strength. They feature interlocking "tails" and "pins" that create a mechanical bond, making them highly resistant to pulling forces. Dovetail joints are often used to connect the aprons to the legs, adding a touch of elegance and sophistication to the table base. However, they require precision and skill to execute accurately.

Dowel joints are a simpler alternative to mortise-and-tenon joints. They involve drilling holes in both pieces of wood and inserting dowels to create a connection. Dowel joints are relatively easy to execute and can be strengthened with glue. They are suitable for connecting the aprons to the legs and stretchers, providing adequate strength for most dining table bases.

Pocket-hole joints are a quick and convenient option for assembling table bases. They involve drilling angled holes into one piece of wood and then attaching it to another piece using screws. Pocket-hole joints are easy to execute and require minimal tools. However, they are not as strong as mortise-and-tenon or dovetail joints. They are best suited for connecting the aprons to the legs, where the screws can be hidden from view.

Screw joints are the simplest and most basic method of joining wood. They involve directly screwing one piece of wood to another. Screw joints are easy to execute but are not as strong or aesthetically pleasing as other joinery methods. They are best used for temporary connections or for attaching secondary components to the table base.

Regardless of the chosen joinery method, precise measurements and accurate cuts are essential for a successful outcome. A slight error in measurement can result in a misaligned joint, compromising the structural integrity of the table base. It is advisable to use a combination square, a measuring tape, and a sharp pencil to ensure accuracy. Power tools, such as a table saw, a miter saw, and a router, can greatly facilitate the cutting and shaping of the wood. However, safety precautions should always be observed when operating power tools.

Assembly and Finishing

Once the individual components of the table base have been cut, shaped, and joined, it is time to assemble the base. The assembly process should be carried out in a systematic and organized manner to ensure proper alignment and stability. It is advisable to use clamps to hold the components together while the glue dries. The clamps should be positioned strategically to apply even pressure and prevent warping or twisting.

Before applying the glue, it is crucial to dry-fit the components to ensure that they fit together properly. A dry-fit allows you to identify any potential problems and make necessary adjustments before committing to the final assembly. Once you are satisfied with the fit, you can apply a thin layer of glue to the mating surfaces. Use a high-quality wood glue that is specifically formulated for furniture construction. The glue should be applied evenly to ensure a strong and durable bond. After applying the glue, clamp the components together and allow them to dry completely. The drying time will vary depending on the type of glue used, but it is generally recommended to let the glue dry for at least 24 hours.

After the glue has dried, remove the clamps and inspect the table base for any imperfections, such as gaps, splinters, or rough edges. Use sandpaper to smooth out any imperfections and create a uniform surface. Start with a coarse grit sandpaper (e.g., 80-grit) and gradually work your way up to a finer grit (e.g., 220-grit). Sand with the grain of the wood to avoid scratching or damaging the surface.

The final step in building a dining table base is to apply a finish. The finish serves to protect the wood from moisture, scratches, and stains, while also enhancing its natural beauty. Several types of finishes are available, including stain, varnish, lacquer, and oil. The choice of finish depends on the desired aesthetic and the level of protection required.

Stain is used to change the color of the wood. It penetrates the wood fibers and imparts a rich, even color. Stain is available in a wide range of colors, from light to dark. It is important to choose a stain that complements the wood species and the overall design of the table base. After applying the stain, it is crucial to apply a clear coat of varnish or lacquer to protect the stain and provide a durable finish.

Varnish is a durable and water-resistant finish that provides excellent protection against scratches and stains. It is available in various sheens, from matte to gloss. Varnish is typically applied in multiple coats, with sanding in between each coat. This creates a smooth, even surface that is resistant to damage.

Lacquer is a fast-drying finish that provides a hard, durable surface. It is often used in commercial furniture manufacturing due to its speed and efficiency. Lacquer is typically applied with a spray gun, requiring specialized equipment and skills.

Oil finishes, such as linseed oil or tung oil, penetrate the wood fibers and provide a natural, matte finish. They are easy to apply and maintain, but they do not provide as much protection as varnish or lacquer. Oil finishes enhance the natural grain and color of the wood, creating a warm and inviting atmosphere.

Regardless of the chosen finish, it is important to follow the manufacturer's instructions carefully. Apply the finish in a well-ventilated area and wear appropriate safety gear, such as a respirator and gloves. Allow the finish to dry completely before using the table base.

Ensuring Stability and Levelness

Once the table base is fully assembled and finished, the final step is to ensure that it is stable and level. This is essential for preventing wobbling and ensuring a comfortable dining experience. Place the table base on a flat, level surface and check for any movement or rocking. Use a level to verify that the top surface is perfectly horizontal.

If the table base is not level, there are several ways to correct the problem. One option is to use adjustable feet, which can be screwed into the bottom of the legs. Adjustable feet allow you to fine-tune the height of each leg, ensuring that the table base is perfectly level. Another option is to use shims, which are thin pieces of wood or plastic that can be placed under the legs to compensate for uneven surfaces.

If the table base is wobbly, it may be necessary to reinforce the joints. This can be done by adding metal brackets or gussets to the corners of the base. The brackets or gussets will provide additional support and prevent the base from flexing or twisting. Alternatively, the legs can be strengthened with additional stretchers.

Attaching the table top securely to the base is critical for stability and safety. The method of attachment will depend on the design of the base and the type of tabletop material. Common methods include using screws, bolts, or metal clips. It is important to use appropriate fasteners and to ensure that they are properly tightened. The connection between the tabletop and the base should be strong and secure to prevent the tabletop from shifting or falling off.

Diy Wood Pedestal Table Base The Inspired Work

Diy Round Table Wood Designs Dining Furniture

How To Build A Diy Dining Table With Cross Legs Thediyplan

Round Scalloped Fluted Pedestal Dining Table Diy Seats 10 12 People Black Ink Oak Finish

Diy Wood Pedestal Table Base The Inspired Work

Diy X Base Circular Dining Table Jaime Costiglio

Build A Simple Diy Pedestal Table Base Easy Steps With Abbotts At Home

How To Build A Diy Dining Table With Angled Trestle Legs

Diy Wood Pedestal Table Base The Inspired Work

Diy X Base Circular Dining Table Jaime Costiglio

Related Posts