How To Make A Dining Table Out Of Scaffold Boards: DIY Ideas

Creating a dining table from scaffold boards is a rewarding do-it-yourself project. It offers an opportunity to craft a unique piece of furniture that adds character and rustic charm to a dining space. This project is suitable for individuals with basic woodworking skills and access to essential tools. Scaffold boards, typically used in construction, present a cost-effective and durable material for furniture making. This article outlines the process of constructing a dining table using scaffold boards, highlighting essential steps and providing design ideas.

Acquiring and Preparing Scaffold Boards

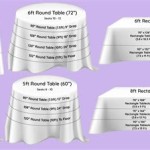

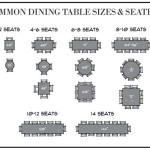

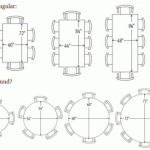

The initial step involves sourcing suitable scaffold boards. These boards are readily available from construction suppliers, timber merchants, and online marketplaces. When selecting boards, it is crucial to consider their condition. Look for boards that are relatively straight, free from significant splits or warping, and of a consistent thickness. The required number of boards will depend on the desired size of the dining table. A standard dining table designed to seat four to six people typically requires four to six boards, depending on their width.

Once the boards are acquired, thorough cleaning and preparation are essential. Scaffold boards often bear traces of construction work, including dirt, debris, and paint splatters. Begin by removing any loose debris with a stiff brush or scraper. Use a suitable cleaning solution, such as a wood cleaner specifically designed for removing grease and grime, to wash the boards thoroughly. Rinse the boards with clean water and allow them to dry completely before proceeding.

After cleaning, the boards require sanding to achieve a smooth and uniform surface. Begin with a coarse-grit sandpaper (e.g., 80-grit) to remove any remaining imperfections and rough patches. Progress to medium-grit sandpaper (e.g., 120-grit) to refine the surface further. For a fine finish, use fine-grit sandpaper (e.g., 220-grit). Sand along the grain of the wood to avoid creating scratches. Power sanders can expedite the sanding process, but care must be taken to avoid over-sanding, which can alter the shape of the boards. Remember to wear a dust mask and safety glasses while sanding to protect from airborne particles.

Addressing any imperfections in the boards is crucial for achieving a professional-looking finished product. Knotholes, cracks, and splits can be filled with wood filler. Apply the wood filler liberally to the affected areas and allow it to dry completely according to the manufacturer's instructions. Once dry, sand the filled areas flush with the surrounding wood surface. For larger gaps or splits, consider using wood epoxy, which provides a more durable and water-resistant repair.

Designing the Table Base and Structure

The table base is a critical component of the dining table, providing stability and structural support. Numerous design options are available, ranging from simple, minimalist designs to more elaborate and decorative structures. Choosing a base design that complements the aesthetic of the scaffold boards and the overall style of the dining space is important.

One popular option is a metal frame base. Metal frames offer a modern and industrial look that contrasts well with the rustic nature of the scaffold boards. These frames can be fabricated from square or rectangular steel tubing, and can be welded or bolted together. Pre-fabricated metal table legs are also readily available from furniture suppliers and online retailers.

Another option is a wooden base crafted from timber. Similar to the scaffold boards themselves, treated lumber or reclaimed wood can be used. Wooden bases can be constructed in various styles, including trestle legs, splayed legs, or a solid pedestal base. A wooden base provides a cohesive and harmonious look when paired with a scaffold board tabletop.

Regardless of the chosen base design, it is important to ensure that the base is appropriately sized and strong enough to support the weight of the tabletop. The base should be securely attached to the tabletop using screws, bolts, or other suitable fasteners. Predrilling pilot holes before inserting screws or bolts is essential to prevent the wood from splitting. Consider using metal inserts in the wood to strengthen the connection points and prevent pull-out.

Bracing elements can be added to the table base to further enhance its stability. Cross braces, diagonal braces, or aprons can be incorporated into the design to prevent wobbling and ensure that the table remains sturdy over time. The specific type and placement of the bracing elements will depend on the design of the base and the size of the tabletop.

When attaching the tabletop to the base, ensure the boards are positioned evenly and securely. Using a level is highly recommended to make sure the table is flat and stable. Small adjustments can be made by using shims if necessary.

Finishing and Protecting the Tabletop

Applying a suitable finish to the tabletop is essential for protecting the wood from moisture, stains, and wear and tear. The choice of finish will depend on the desired aesthetic and the level of protection required. Several options are available, each with its own advantages and disadvantages.

One popular option is varnish. Varnish provides a durable and water-resistant finish that protects the wood from scratches and stains. It is available in various sheens, ranging from matte to gloss. Applying multiple coats of varnish is recommended for optimal protection. Sand lightly between coats to ensure a smooth finish.

Another option is oil-based finish. Oil-based finishes penetrate the wood, enhancing its natural grain and providing a warm, rich tone. They offer good protection against moisture and stains, but they may require more frequent reapplication than varnish. Tung oil and linseed oil are common choices for oil-based finishes.

Water-based finishes are also available. These finishes are environmentally friendly and offer good protection against moisture and stains. They typically dry faster than oil-based finishes and are available in various sheens. However, they may not provide the same level of durability as varnish or oil-based finishes.

Before applying any finish, it is important to ensure that the tabletop is clean and free from dust or debris. Apply the finish evenly using a brush, roller, or spray gun. Follow the manufacturer's instructions carefully regarding application techniques, drying times, and safety precautions.

Consider using a sealant primer on the tabletop before applying the finishing coat. Sealant primers help to prevent the finish from being absorbed unevenly into the wood, resulting in a more consistent and uniform finish. They also help to seal any remaining imperfections in the wood surface.

After the final coat of finish has dried completely, consider applying a wax or sealant to further protect the tabletop. Wax adds a layer of protection against scratches and stains, while also enhancing the sheen of the finish. Sealants provide additional protection against moisture penetration.

Adding personalized touches is a final step in the process. This could involve staining the wood to a specific shade that complements the dining room decor. Alternatively, consider painting the base for a pop of color or adding metal accents for an industrial feel. The specific treatments applied will depend on the overall design aesthetic that is desired.

Regular maintenance is important to keep the scaffold board dining table looking its best. Clean the tabletop regularly with a damp cloth to remove dirt and spills. Avoid using harsh cleaning chemicals, which can damage the finish. Apply a furniture polish or wax periodically to protect the finish and enhance its sheen.

By following these steps, individuals can create a unique and durable dining table from scaffold boards that will be a focal point of their dining space. This project combines cost-effectiveness with the satisfaction of crafting a piece of furniture that is both functional and aesthetically pleasing. The inherent characteristics of scaffold boards lend themselves to a variety of design styles, making this a versatile option for DIY enthusiasts.

Diy Scaffold Board Dining Table And Bench

How To Make An Industrial Rustic Scaffold Board Dining Table And Bench

Makeover A Dining Table Made From Scaffold Boards Roses And Rolltops

How To Make An Industrial Rustic Scaffold Board Dining Table And Bench

How To Make A 4 6 Seater Dining Table From Reclaimed Scaffold Boards Friday Ad Blog

.jpg.aspx?strip=all)

How To Make A Table Out Of Scaffold Boards Upcycling Safe

Diy Scaffold Board Dining Table And Bench

How To Make A Table Out Of Scaffold Boards Upcycling Safe

How To Build A Scaffold Board Table Prevent Cupping

Makeover A Dining Table Made From Scaffold Boards Roses And Rolltops

Related Posts