DIY Round Dining Table Base: A Comprehensive Guide

Creating a custom dining table provides an opportunity to personalize the centerpiece of a dining space. While sourcing a tabletop might involve selecting the right wood, finish, or even repurposing an existing surface, constructing the table base offers a particularly rewarding DIY experience. A round dining table base, in particular, presents unique design and structural considerations. This article details the process of designing and building a round dining table base, outlining various design options, material selections, and construction techniques.

The selection of a suitable base design significantly impacts the table's overall stability, aesthetics, and functionality. Moreover, understanding the structural requirements for supporting a round tabletop is crucial for a successful build. This guide aims to equip readers with the knowledge and resources necessary to embark on their own DIY round dining table base project.

Planning and Design Considerations

Before commencing the physical construction of a round dining table base, a thorough planning phase is essential. This phase involves considering the desired aesthetic, the table's intended use, and the available resources. Several key factors deserve careful attention during the planning stage.

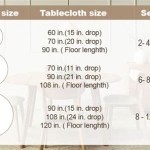

Tabletop Dimensions:

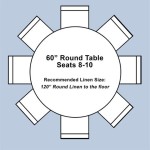

The diameter and thickness of the round tabletop directly influence the dimensions and stability requirements of the base. A larger diameter tabletop necessitates a wider and more robust base to prevent tipping or wobbling. The thickness of the tabletop also affects the load the base must support. Measure the tabletop precisely to inform the design process.Desired Height:

Standard dining table heights typically range from 28 to 30 inches. Subtract the thickness of the tabletop from the desired total height to determine the necessary height of the base. Consider the intended use of the table and the height of the chairs that will be used with it. A bar-height round table, for example, will require a significantly taller base.Aesthetic Preferences:

The design of the base should complement the tabletop and the overall style of the dining space. Options range from minimalist metal designs to rustic wooden structures. Consider the materials, shapes, and finishes that align with the desired aesthetic. Gather inspiration from existing furniture and design magazines to inform the design choices.Structural Stability:

The base must be structurally sound to support the weight of the tabletop and withstand everyday use. The design should distribute the weight evenly and prevent any instability. Consider the load-bearing capacity of the materials and the joinery methods used. Overengineering the base is often preferable to risking instability.Material Selection:

The choice of materials impacts both the aesthetics and the structural integrity of the base. Wood, metal, and concrete are common choices, each offering distinct advantages and disadvantages. Wood offers warmth and versatility, metal provides strength and a modern aesthetic, and concrete offers industrial appeal and substantial weight. Consider the cost, availability, and workability of each material.Design Options:

Numerous design options exist for a round dining table base. Common designs include pedestal bases, tripod bases, four-legged bases, and geometric designs. Pedestal bases feature a central support column, while tripod bases offer stability with three legs. Four-legged bases are a traditional option, and geometric designs allow for creative expression. Each design offers unique aesthetic and structural properties.Material Selection and Preparation

The selection of appropriate materials is crucial for constructing a durable and aesthetically pleasing round dining table base. The choice of material influences the overall design, stability, and longevity of the finished product. Proper preparation of the chosen materials is equally important to ensure a successful build.

Wood:

Wood is a versatile and widely used material for DIY projects. Hardwoods such as maple, oak, and walnut offer excellent strength and durability. Softwoods such as pine and fir are more affordable but may require additional reinforcement. When selecting wood, ensure it is properly dried and free from defects such as knots, cracks, or warping. Proper drying prevents the wood from shrinking or expanding after construction.Metal:

Metal offers a modern and industrial aesthetic. Steel is a strong and durable option, while aluminum is lightweight and corrosion-resistant. Metal can be welded, bolted, or screwed together to create a sturdy base. When working with metal, consider the need for specialized tools and equipment, such as a welding machine or metal-cutting saw. Surface preparation, such as sanding and priming, is essential to prevent rust and corrosion.Concrete:

Concrete provides a unique and substantial base option. It offers excellent stability and an industrial aesthetic. Working with concrete requires specialized techniques and equipment, such as molds and mixing tools. Concrete can be poured into custom molds to create unique shapes and designs. Proper curing is essential to ensure the concrete reaches its full strength. Reinforcement with steel rebar or wire mesh can enhance the structural integrity of the concrete base.Material Preparation:

Regardless of the chosen material, proper preparation is crucial. Wood should be sanded smooth and sealed with a primer or finish. Metal should be cleaned and primed to prevent rust. Concrete should be mixed according to the manufacturer's instructions and poured into well-prepared molds. Accurate measurements and precise cuts are essential for creating a stable and aesthetically pleasing base. Use appropriate safety equipment, such as safety glasses and gloves, when working with any material.Construction Techniques and Considerations

The actual construction of the round dining table base involves various techniques depending on the chosen design and materials. Understanding these techniques and addressing potential challenges is crucial for a successful build.

Wood Joinery:

When working with wood, various joinery techniques can be employed to create strong and durable connections. Common techniques include mortise and tenon joints, dovetail joints, and screw or dowel joints. Mortise and tenon joints offer excellent strength and stability, while dovetail joints provide a visually appealing and robust connection. Screw or dowel joints are simpler to execute but may require additional reinforcement. Selecting the appropriate joint type depends on the design, the load-bearing requirements, and the skill level of the builder.Metal Fabrication:

Metal fabrication involves cutting, welding, and shaping metal to create the desired base structure. Welding is the most common method for joining metal components, providing a strong and permanent bond. Cutting metal can be achieved with a metal-cutting saw, angle grinder, or plasma cutter. Shaping metal may involve bending, rolling, or forging, depending on the design. Ensure proper ventilation and wear appropriate safety equipment when welding or cutting metal. Grinding and finishing the welds are essential to create a smooth and aesthetically pleasing surface.Concrete Casting:

Casting concrete involves pouring a wet concrete mixture into a mold and allowing it to cure. The mold can be made from wood, plastic, or metal. The interior of the mold should be smooth and clean to ensure a uniform surface on the finished concrete base. Reinforcement with steel rebar or wire mesh can enhance the structural integrity of the concrete. Vibrating the mold during the pouring process helps to remove air bubbles and ensure a dense and solid concrete structure. Proper curing, which involves keeping the concrete moist for several days, is essential for achieving maximum strength and durability.Assembly and Finishing:

After the individual components are fabricated, the base is assembled. This may involve bolting, screwing, or gluing the pieces together. Ensure all connections are secure and stable. The finishing process involves sanding, painting, staining, or applying a protective coating to the base. This enhances the aesthetics of the base and protects it from wear and tear. Select a finish that complements the tabletop and the overall style of the dining space. Allow the finish to dry completely before attaching the tabletop to the base.Attaching the Tabletop:

Securely attaching the tabletop to the base is crucial for ensuring the stability of the dining table. Various methods can be used, including screws, bolts, or adhesive. Screws can be driven through the base and into the underside of the tabletop, ensuring they are long enough to provide a secure hold but not so long that they penetrate the top surface. Bolts can be used with threaded inserts in the tabletop for a more robust connection. Adhesive can be used in conjunction with screws or bolts for added strength. Ensure the tabletop is centered on the base and that all connections are tight and secure.Addressing Stability Issues:

If the table is wobbly or unstable, several adjustments can be made. Leveling feet can be added to the base to compensate for uneven floors. Shims can be placed under the legs or base to correct any imbalances. Adding weight to the base can also improve stability. If the problem persists, the design may need to be modified or the connections strengthened. Addressing stability issues early on can prevent future problems and ensure a safe and enjoyable dining experience.Building a DIY round dining table base is a rewarding project that allows for customization and creative expression. By carefully planning the design, selecting appropriate materials, and employing proper construction techniques, individuals can create a beautiful and functional centerpiece for their dining space. The considerations outlined in this guide provide a solid foundation for embarking on this DIY endeavor.

Round Scalloped Fluted Pedestal Dining Table Diy Seats 10 12 People Black Ink Oak Finish

Diy X Base Circular Dining Table Jaime Costiglio

How To Build A 70 Round Dining Table Honey Built Home

Round Dining Table How To Build An X Base

How To Build A Dining Room Table Diy

Diy X Base Circular Dining Table Jaime Costiglio

How To Build A 70 Round Dining Table Honey Built Home

Diy Wood Pedestal Table Base The Inspired Work

How To Build A Round Pedestal Dining Table Plan Available

Round Scalloped Fluted Pedestal Dining Table Diy Seats 10 12 People Black Ink Oak Finish

Related Posts