DIY Round Dining Table Legs: A Comprehensive Guide

Constructing a dining table is a rewarding DIY project, allowing for customization and personalization that pre-made furniture often lacks. The legs are a crucial component, influencing the table's stability, aesthetic, and overall design. Opting for round dining table legs offers a softer, more contemporary look compared to traditional square or rectangular legs. This article provides a detailed guide to crafting round dining table legs, covering design considerations, material selection, construction techniques, and finishing options.

Design Considerations and Planning

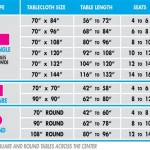

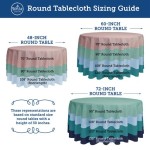

Before commencing the physical construction, meticulous planning is essential. The design phase should encompass the table's intended use, overall style, and the desired dimensions. The diameter of the round tabletop dictates the number and placement of the legs needed for adequate support. A smaller table (e.g., 36-48 inches in diameter) may suffice with three legs placed equidistant around the perimeter, while larger tables (e.g., 60 inches or more) generally require four legs positioned closer to the table's corners. The leg height determines the table's overall height, which typically ranges from 28 to 30 inches for standard dining tables. Consider the chairs that will be used with the table to ensure there is adequate legroom.

The desired aesthetic plays a significant role in leg design. Simple, straight cylindrical legs offer a minimalist and modern aesthetic. Tapered legs, narrower at the top and widening towards the bottom, provide a more elegant and refined appearance. The design can also incorporate decorative elements such as fluting, carvings, or metal accents. Sketching different leg designs and visualizing them with the tabletop can aid in making informed decisions. Software tools, even simple 2D drawing programs, can be useful for creating scaled-down prototypes and visualizing the final product.

The attachment method is another critical design consideration. Legs can be attached directly to the tabletop using screws and wood glue, employing metal brackets, or utilizing a separate apron (a supporting frame beneath the tabletop). The chosen attachment method impacts the leg design. For example, if using metal brackets, the legs need to have a flat surface for secure attachment. If incorporating an apron, the legs can be mortised and tenoned into the apron for enhanced stability. Careful consideration of the attachment method early in the design phase will ensure a strong and durable connection between the legs and the tabletop.

Material Selection and Preparation

The choice of material significantly impacts the table's appearance, durability, and cost. Hardwoods such as maple, oak, walnut, and cherry are common choices for dining table legs due to their strength, stability, and aesthetic appeal. Softwoods like pine and fir are less expensive but may not be as durable or resistant to dents and scratches. Engineered wood products like MDF (Medium-Density Fiberboard) can be used for legs, but they typically require careful sealing and painting to prevent moisture damage. A sustainable option is reclaimed wood, offering a unique character and reducing environmental impact.

Once the material is selected, it must be properly prepared before shaping the legs. This involves selecting lumber with straight grains and minimal knots. The lumber should be kiln-dried to minimize warping and cracking after construction. Use a jointer and planer to create flat, square boards that are consistent in thickness. This ensures that the legs are uniform in size and shape. Accurately measuring and marking the lumber is crucial for achieving the desired leg dimensions. The marking process should include the leg's length, diameter, and any tapers or decorative features.

Safety is paramount during material preparation. Wear appropriate safety gear, including safety glasses, hearing protection, and a dust mask or respirator. Ensure that all power tools are in good working condition and used according to the manufacturer's instructions. Securely clamp the lumber to a workbench to prevent movement during cutting and shaping. Take breaks to avoid fatigue, which can lead to accidents. A well-organized and safe workspace is essential for successful and injury-free DIY projects.

Construction Techniques for Round Legs

Several techniques can be employed to create round table legs. One common method involves using a lathe, a power tool that rotates the wood while a cutting tool is used to shape it. This is the most efficient way to create perfectly round and uniformly shaped legs, especially when producing multiple legs of the same design. After mounting the squared lumber between the lathe's headstock and tailstock, various shaping tools are used to gradually round the wood and create the desired profile. Practice and careful control of the cutting tools are essential for achieving consistent results.

For those without access to a lathe, alternative methods exist. One option is to use a router with a rounding-over bit. This involves creating a square or rectangular leg blank and then using the router to round off the corners. Multiple passes with the router may be required to achieve a fully rounded profile. A jig can be built to guide the router and ensure consistent results. This method requires careful attention to detail and a steady hand to avoid uneven rounding. Sanding is crucial after routing to smooth any imperfections and create a consistent surface.

Another alternative involves using a drawknife and spokeshave. This is a more traditional woodworking technique that requires skill and patience, but it can produce beautiful and unique results. The drawknife is used to remove large amounts of wood, while the spokeshave is used for finer shaping and smoothing. This method allows for greater control over the leg's shape and profile, but it also requires more time and effort compared to using power tools. Hand tools can be used for creating decorative elements like tapers or coves.

Regardless of the chosen method, consistent measurements and careful attention to detail are essential for creating uniform legs. Regularly check the leg's dimensions and shape to ensure they match the design specifications. Sanding is an important step in the construction process, smoothing out any imperfections and preparing the legs for finishing. Start with coarser grit sandpaper and gradually progress to finer grits to achieve a smooth and even surface.

Finishing and Installation

The finishing process enhances the wood's beauty and protects it from moisture, scratches, and other damage. Various finishing options are available, each offering a different aesthetic and level of protection. Stain can be used to enhance the wood's natural color or to create a completely different look. Varnish, lacquer, and polyurethane are durable topcoats that provide a protective layer and can be applied in different sheens, from matte to gloss. Oil finishes, such as tung oil or linseed oil, penetrate the wood and provide a natural look and feel. Wax finishes can be applied over oil finishes for added protection and luster.

Before applying the finish, the legs must be thoroughly sanded and cleaned. Any dust or debris can interfere with the finish and create an uneven surface. Apply the finish in thin, even coats, following the manufacturer's instructions. Allow each coat to dry completely before applying the next. Sand lightly between coats with fine-grit sandpaper to remove any imperfections and ensure a smooth finish. The number of coats required depends on the type of finish and the desired level of protection.

Once the finish is dry, the legs can be attached to the tabletop. As previously discussed, the attachment method depends on the design and the desired level of stability. When using screws and wood glue, pre-drill pilot holes to prevent the wood from splitting. Apply wood glue to the mating surfaces and clamp the legs securely to the tabletop until the glue is dry. For metal brackets, align the brackets carefully and screw them into both the legs and the tabletop. When using an apron, mortise and tenon joints provide a strong and stable connection between the legs and the apron. Once the legs are attached, inspect the table for stability and make any necessary adjustments. Leveling feet can be added to the bottom of the legs to compensate for uneven floors.

Round Scalloped Fluted Pedestal Dining Table Diy Seats 10 12 People Black Ink Oak Finish

Trestle Legs For Round Table Diy Wood

Round Modern Dining Table Base Ana White

Diy Simplistic Circular Dining Table Kreg Tool

Diy X Base Circular Dining Table Jaime Costiglio

Salvaged Wood Beam Round Dining Table The Created Home

Diy Round Table Kitchen Wood Pedestal Base

Diy How To Build A Round Outdoor Dining Table Building Strong

How To Build A 70 Round Dining Table Honey Built Home

Diy Round Table Wood Designs Dining Furniture Plans

Related Posts