How to Make a Dining Table From Scaffold Boards

Creating a dining table from scaffold boards is a rewarding and cost-effective project that allows for a custom-built piece of furniture with a rustic and industrial aesthetic. This article provides a comprehensive guide to constructing a sturdy and visually appealing dining table using reclaimed or new scaffold boards. The instructions encompass material selection, preparation, assembly, and finishing techniques.

The appeal of a scaffold board dining table lies in its unique character. Each board, especially when reclaimed, bears the marks of its previous life, adding depth and history to the piece. This contrasts sharply with mass-produced furniture, offering a one-of-a-kind centerpiece for the dining room. The project also encourages sustainable practices by repurposing materials and promoting a more environmentally conscious approach to home furnishings.

This construction project requires basic woodworking knowledge and the use of power tools. Safety precautions should be observed at all times. Eye protection, ear protection, and respiratory protection are essential when cutting, sanding, and applying finishes. Work in a well-ventilated area, particularly when dealing with paints, stains, and varnishes.

Key Point 1: Material Selection and Preparation

The first and arguably most crucial step is selecting the appropriate scaffold boards. Both reclaimed and new boards can be utilized, each offering distinct advantages. Reclaimed boards boast a weathered appearance and unique imperfections, while new boards provide a consistent and uniform surface that requires less preparation. The choice depends on the desired aesthetic of the finished table.

When choosing reclaimed boards, inspect them carefully for structural integrity. Avoid boards with excessive warping, rot, or large cracks. Small knots and minor imperfections are acceptable and contribute to the rustic charm. Thoroughly clean the boards to remove dirt, debris, and any lingering concrete residue. A pressure washer can be effective, but ensure the boards are allowed to dry completely before further processing.

New scaffold boards, while cleaner, may still require some sanding to smooth any rough edges or splinters. Consider the timber type when selecting new boards. European whitewood is a common choice, offering a light color and relatively soft texture that is easy to work with. Redwood is another option, providing a richer color and greater resistance to decay.

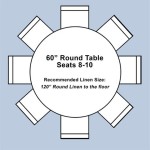

The required number of boards will depend on the desired dimensions of the table. Standard scaffold boards are typically 225mm wide, allowing for easy calculation of the table's width. The length of the boards will determine the table's length. Ensure the boards are sufficiently long to accommodate the intended seating arrangement. Plan for approximately 600mm of table length per person for comfortable dining.

In addition to the scaffold boards, consider the support structure for the table. Metal hairpin legs are a popular choice for their industrial aesthetic and ease of installation. Alternatively, wooden legs can be crafted from solid timber for a more traditional look. The height of the legs should be approximately 710-760mm to achieve a standard dining table height.

Once the boards are selected, they need to be cut to the desired length. Use a circular saw or a hand saw for accurate and clean cuts. Clamping the boards to a workbench will ensure stability during the cutting process. Measure and mark the cut lines precisely to avoid errors. If multiple boards are being used for the tabletop, cut them all to the same length for a uniform appearance.

Key Point 2: Assembling the Tabletop

Before joining the boards together, consider the desired arrangement of the grain and any imperfections. Experiment with different configurations to achieve the most visually appealing layout. Once the arrangement is finalized, the boards can be joined using a variety of methods.

One common method is to use wood glue and clamps. Apply a generous amount of wood glue to the edges of each board and clamp them together tightly. Ensure the boards are aligned flush and that the clamps are evenly distributed along the length of the boards. Allow the glue to dry completely according to the manufacturer's instructions, typically at least 24 hours.

Another option is to use pocket hole joinery. This involves drilling angled holes into the underside of the boards and securing them together with screws. Pocket hole joinery provides a strong and concealed connection, making it a popular choice for woodworking projects. A pocket hole jig is required for accurate and consistent drilling.

For additional support, consider adding breadboard ends to the tabletop. Breadboard ends are strips of wood that are attached to the ends of the table, perpendicular to the main boards. They help to prevent warping and cupping of the tabletop and add a decorative element. Breadboard ends are typically attached using mortise and tenon joints, which require more advanced woodworking skills.

After the boards are joined, the tabletop surface should be sanded smooth. Start with a coarse grit sandpaper (e.g., 80 grit) to remove any imperfections or irregularities. Progress to finer grits (e.g., 120 grit, 220 grit) to achieve a smooth and even surface. A random orbital sander is recommended for efficient and consistent sanding. Pay particular attention to the edges of the tabletop, ensuring they are rounded over slightly to prevent sharp corners.

Once sanding is complete, thoroughly clean the tabletop to remove any dust and debris. A tack cloth can be used to pick up any remaining particles. The tabletop is now ready for finishing.

Key Point 3: Finishing and Protecting the Table

The finishing process is crucial for protecting the wood and enhancing its natural beauty. The choice of finish depends on the desired aesthetic and the intended use of the table. Options include varnish, lacquer, oil, wax, and paint. Each finish offers different levels of protection, durability, and sheen.

Varnish is a durable and protective finish that provides a hardwearing surface. It is available in a variety of sheens, from matte to gloss. Apply varnish in thin, even coats using a brush or a spray gun. Allow each coat to dry completely before applying the next. Sand lightly between coats to remove any imperfections and ensure a smooth finish.

Lacquer is another durable finish that is often used on furniture. It provides a smooth and glossy surface that is resistant to scratches and stains. Lacquer is typically applied using a spray gun, and it requires proper ventilation due to its strong fumes.

Oil finishes, such as tung oil or linseed oil, penetrate the wood and enhance its natural grain. They provide a subtle sheen and require regular maintenance. Apply oil finishes in thin coats using a cloth or brush. Allow the oil to soak into the wood for a few minutes before wiping off the excess. Repeat the application process several times for optimal protection.

Wax finishes, such as beeswax or carnauba wax, provide a soft and lustrous sheen. They are easy to apply and maintain, but they offer less protection than varnish or lacquer. Apply wax finish in thin coats using a cloth. Buff the surface with a clean cloth to achieve a smooth and polished finish.

Paint can be used to completely transform the appearance of the table. Choose a paint that is specifically designed for furniture and follow the manufacturer's instructions carefully. Apply primer before painting to ensure proper adhesion and a uniform finish. Apply several coats of paint, allowing each coat to dry completely before applying the next. Sand lightly between coats to remove any imperfections.

Regardless of the chosen finish, apply it evenly and according to the manufacturer's instructions. Allow the finish to cure completely before using the table. This will ensure that the finish is durable and protective.

Once the finish is dry, attach the legs to the tabletop. Position the legs evenly and securely fasten them using screws or bolts. Ensure the legs are properly aligned to prevent the table from wobbling. Leveling feet can be added to the legs to compensate for any unevenness in the floor.

Finally, inspect the completed table for any imperfections or areas that need attention. Touch up any scratches or blemishes with the chosen finish. Clean the table with a damp cloth and mild soap to remove any dust or debris. The dining table is now ready for use.

Makeover A Dining Table Made From Scaffold Boards Roses And Rolltops

How To Make An Industrial Rustic Scaffold Board Dining Table And Bench

Diy Scaffold Board Dining Table And Bench

How To Make A Table Out Of Scaffold Boards Upcycling Safe

How To Build A Scaffold Board Dining Table With Hairpin Legs

How To Make An Industrial Rustic Scaffold Board Dining Table And Bench

.jpg.aspx?strip=all)

How To Make A Table Out Of Scaffold Boards Upcycling Safe

.jpg.aspx?strip=all)

How To Make A Table Out Of Scaffold Boards Upcycling Safe

Makeover A Dining Table Made From Scaffold Boards Roses And Rolltops

Diy Scaffold Board Dining Table And Bench

Related Posts