How To Make A Table Pedestal

Creating a table pedestal represents a fulfilling woodworking project, offering both functional utility and aesthetic appeal. A well-constructed pedestal can significantly enhance the stability and visual elegance of a table, particularly for round or oval tabletops. This article provides a comprehensive guide to crafting a table pedestal, outlining essential steps, material considerations, and construction techniques necessary for a successful outcome.

Before embarking on the project, careful planning and preparation are crucial. This initial phase involves determining the desired dimensions of the pedestal, selecting appropriate materials, and acquiring necessary tools. The height of the pedestal must be determined to ensure the table achieves a comfortable dining or working height. The diameter of the base should also be calculated based on the size and weight of the intended tabletop to guarantee stability. The design aesthetic, be it traditional, modern, or rustic, should also be finalized at this stage as it will influence material choices and construction methods.

Material selection is a primary factor influencing both the durability and the visual character of the table pedestal. Hardwoods, such as maple, oak, cherry, and walnut, are commonly preferred for their strength, resistance to wear, and attractive grain patterns. Softwoods, like pine or fir, can be used for more rustic or budget-conscious projects, but they require careful finishing and may not offer the same level of long-term durability. The specific type of wood chosen should complement the tabletop material and the overall design scheme. In addition to wood, consider the use of metal accents or supports to enhance the structural integrity or visual appeal of the pedestal.

The tools required for constructing a table pedestal typically include a table saw, miter saw, router, drill, sander, and various hand tools such as chisels, planes, and clamps. Precision is paramount in woodworking, so accurate measuring tools like a tape measure, square, and level are indispensable. Safety equipment, including safety glasses, hearing protection, and a dust mask, should always be worn when operating power tools or working with wood. A well-equipped workshop will streamline the construction process and improve the overall quality of the finished product.

Determining the Pedestal Design and Dimensions

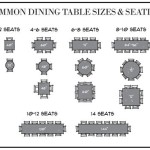

The design of a table pedestal can vary widely, ranging from simple cylindrical shapes to more complex, multi-faceted structures. The chosen design must not only be visually appealing but also structurally sound enough to support the weight of the tabletop. For instance, a large, heavy tabletop requires a more substantial pedestal base than a smaller, lighter one. The height of the pedestal is crucial for ensuring comfortable use of the table; standard dining tables typically have a height of around 28 to 30 inches. The base diameter should be at least 1/3 to 1/2 the diameter of the tabletop to provide adequate stability, preventing tipping or wobbling.

Once the overall dimensions are determined, detailed plans or sketches should be created. These plans should include precise measurements for each component of the pedestal, as well as any angles or curves that need to be cut. Detailed plans serve as a roadmap for the construction process, minimizing errors and ensuring that all parts fit together correctly. Consider using CAD software or online woodworking design tools to create accurate and professional-looking plans. These tools can also help visualize the finished product and identify any potential design flaws before construction begins.

The design phase also encompasses the selection of appropriate joinery techniques. Common joinery methods for table pedestals include mortise and tenon joints, dowel joints, and biscuit joints. Mortise and tenon joints are particularly strong and durable, making them ideal for connecting the pedestal base to the column. Dowel joints and biscuit joints are simpler to execute but may not offer the same level of strength. The choice of joinery technique should be based on the complexity of the design, the type of wood being used, and the desired level of structural integrity.

Constructing the Pedestal Base

The base of the pedestal provides the foundation for the entire table, and its construction is critical for stability. A common approach involves creating a multi-sided base, typically with three or four legs or panels that radiate outward from a central support. These legs can be cut from solid wood or constructed from laminated pieces. The chosen method will depend on the desired aesthetic and the available wood stock.

Accurate cutting is essential for ensuring a tight, gap-free fit between the base components. A miter saw is particularly useful for cutting precise angles on the legs or panels. After cutting, the pieces should be carefully sanded to remove any saw marks or imperfections. The use of a router with a chamfer bit can create a decorative edge on the base components, adding visual interest and softening sharp corners.

The individual base components can be joined using glue and screws, or more traditional joinery methods like mortise and tenon joints. When using glue and screws, ensure that the screws are countersunk to prevent them from interfering with the finishing process. High-quality wood glue should be applied to all mating surfaces to create a strong and durable bond. Clamps should be used to hold the pieces together until the glue has completely dried. After the glue has dried, the base should be thoroughly sanded to ensure a smooth and uniform surface.

Building the Pedestal Column and Top Support

The pedestal column forms the central support structure of the table. It can be constructed from a single piece of wood, or it can be assembled from multiple pieces joined together. The column can have a simple cylindrical shape, or it can be more elaborately designed with curves, flutes, or other decorative elements. A lathe can be used to turn a cylindrical column from a solid block of wood. This process allows for precise shaping and creates a smooth, uniform surface.

If a lathe is not available, the column can be constructed from multiple pieces of wood that are glued and clamped together. This approach allows for the creation of more complex shapes and designs. For example, a square column can be constructed from four pieces of wood that are joined at the corners. The edges of the column can be rounded over with a router to create a softer, more refined appearance.

The top support attaches the pedestal column to the tabletop. This support should be securely fastened to both the column and the tabletop to ensure stability. A common method for attaching the top support is to use screws and glue. The screws should be countersunk to prevent them from interfering with the finishing process. Alternatively, a more elaborate joinery method, such as a mortise and tenon joint, can be used to create a stronger and more durable connection. The shape of the top support should complement the design of the tabletop and the pedestal column. It can be round, square, or any other shape that is aesthetically pleasing and structurally sound.

After the pedestal column and top support have been constructed, they should be carefully sanded to remove any imperfections. The edges should be rounded over with a router to create a smooth and comfortable feel. The surfaces should be thoroughly cleaned to remove any dust or debris before finishing.

The final assembly of the table pedestal involves connecting the base, column, and top support. Glue and screws are typically used to join these components, ensuring a strong and stable structure. The column should be centered on the base and the top support to distribute the weight evenly. Clamps should be used to hold the pieces together until the glue has fully cured. Any gaps or imperfections should be filled with wood putty and sanded smooth. The assembled pedestal should be inspected for stability and alignment before the finishing process begins.

Sanding is a crucial step in preparing the table pedestal for finishing. Start with a coarse grit sandpaper (e.g., 80-grit) to remove any major imperfections, then gradually progress to finer grits (e.g., 120-grit, 220-grit) to achieve a smooth, uniform surface. Sand with the grain of the wood to avoid creating scratches. A random orbital sander can be used for large surfaces, while hand sanding is recommended for intricate details and corners. After sanding, thoroughly remove all dust and debris with a tack cloth or vacuum cleaner.

Finishing the table pedestal protects the wood from moisture, scratches, and other damage. A variety of finishes can be used, including stain, paint, varnish, lacquer, and oil. The choice of finish depends on the desired aesthetic and the type of wood being used. Stain enhances the natural grain of the wood and adds color. Paint provides a solid, opaque finish. Varnish and lacquer are durable clear coats that protect the wood from wear and tear. Oil provides a natural, matte finish that is easy to maintain.

Apply the finish in thin, even coats, following the manufacturer's instructions. Allow each coat to dry completely before applying the next. Lightly sand between coats with fine-grit sandpaper to remove any imperfections and create a smooth surface. Multiple coats of finish are typically required for adequate protection and durability. After the final coat has dried, buff the surface with a soft cloth to create a lustrous sheen.

How To Make An Upcycled Pedestal Dining Table Collective Gen

Diy Wood Pedestal Table Base The Inspired Work

Diy Pedestal Table Base For Square Or Round Dining Room Tables

How To Build A Pedestal Table Base

Ideas On How To Make A Drum Cylinder Table Base Lumberjocks Woodworking Forum

Round Pedestal Table Finewoodworking

J Pedestal Dining Table Rogue Engineer

Diy Coffee Table Easy X Base With Round Top

How To Make A Sculptural Outdoor Table Anthro Dupe Collective Gen

How To Make A Glass Pedestal Table By Yourself

Related Posts